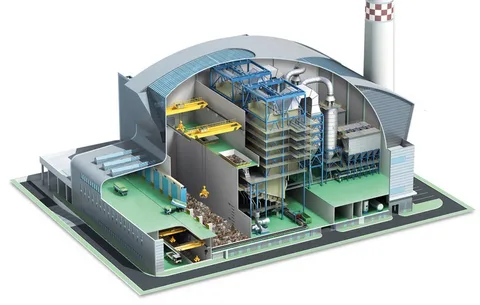

Transforming yesterday’s trash into tomorrow’s electricity once sounded like science fiction, yet waste-to-energy (WTE) plants now anchor many cities’ climate and waste-management strategies. By capturing heat, gases, and useful by-products that would otherwise escape into landfills, these facilities turn disposal costs into power revenue.

The technology stack behind a modern WTE plant is surprisingly sophisticated—touching everything from high-temperature chemistry to cloud-based analytics—all working toward a single goal: squeeze every watt from every wrapper before the remnants head for final processing.

From Garbage to Grid: Thermal Conversion Breakthroughs

At the heart of most WTE facilities is advanced thermal conversion. Today’s moving-grate furnaces and fluidized-bed reactors burn heterogeneous municipal waste far more evenly than older incinerators, driving boiler temperatures above 1,000 °C while sharply reducing unburned hydrocarbons. Integrated heat-recovery steam generators feed high-efficiency turbines that rival those in natural-gas plants.

Plasma-arc gasifiers, still gaining commercial traction, push temperatures past 3,000 °C, separating waste into a synthetic gas rich in hydrogen and carbon monoxide plus an inert, glassy slag suitable for road aggregate. These hotter, cleaner reactions cut dioxin formation and capture metals for recycling, turning what was once a pollution source into a circular-economy engine.

Turning Microbes into Mini Power Plants: Biochemical Digestion

Not all waste needs fire to release its energy. Organic scraps, sewage sludge, and agricultural residues excel in sealed anaerobic digesters where consortia of bacteria break complex molecules into methane-rich biogas. Innovations in pretreatment—such as thermal hydrolysis and ultrasonic disintegration—crack tough cell walls, speeding digestion and raising gas yields by up to 30 percent.

Multi-stage reactors maintain different microbial “neighborhoods” at optimal temperatures and pH levels, ensuring that acid-forming and methane-forming microbes never compete for resources. The resulting biogas, scrubbed of hydrogen sulfide and moisture, spins combined-heat-and-power engines or is upgraded to pipeline-quality renewable natural gas, slashing greenhouse emissions while creating a steady revenue stream.

Digital Brains: Sensors and AI Optimizing Every Watt

Behind the roaring furnaces and bubbling digesters lies an invisible layer of code. Dense sensor networks track temperature gradients, flue-gas composition, steam pressure, and turbine vibration thousands of times per second. Machine-learning models trained on this torrent of data predict slag buildup, fine-tune oxygen injection, and schedule maintenance before a bearing overheats.

Cloud-based supervisory control and data acquisition (SCADA) platforms let engineers dispatch power in real time, responding to grid signals or spot-market prices within minutes. Even citizen waste habits feed the algorithm: municipal collection trucks scan bin volume and composition, sending forecasts so plants can pre-adjust furnace loads or digester feed rates days in advance.

Moving the Molecules: Support Systems That Keep Energy Flowing

High-tech combustion and digestion are useless without the pipes, pumps, and conveyors that keep material and heat on the move. Automated crane claws sort incoming refuse by size and calorific value, directing each batch to the optimal processing line.

Water-cooled induction fans temper flue gases before they reach carbon-capture skids, while heavy-duty sludge pumps transfer ash-laden slurry through multi-stage filtration units that reclaim metals and produce clean process water. Meanwhile, refractory-lined ductwork recycles low-grade heat back into pre-drying tunnels, squeezing extra efficiency without burning an extra ounce of trash.

Conclusion

Waste-to-energy plants no longer rely on brute-force incineration; they orchestrate a symphony of thermal, biochemical, mechanical, and digital technologies that collectively transform garbage into grid power, heat, and valuable by-products. As cities chase aggressive decarbonization goals and landfill space dwindles, the next generation of WTE facilities—smarter, cleaner, and more flexible—will play an even larger role in fueling tomorrow.